Trade Show News

BestCode Brazil at Fispal Tecnologia

June 24-27 2025

It's time to replace your aging and obsolete date coders. It's time to upgrade to BestCode. Visit BestCode Brazil at the São Paulo Expo, street J - booth 42.

News: BestCode in Action—Food Manufacturing

BestCode Ukraine (Promark)

June 11, 2025

It’s time to upgrade to BestCode and replace those aging date coders. Owners of food products, it's time to count every drop! BestCode uses only 3 ml of solvent per hour - versus 40 ml of competitors. Mark wisely. Save with BestCode.

In the Headlines

CIJ Printing Upgrade Underway at Yuengling—America’s oldest brewery, D.G. Yuengling & Son, Inc.

CIJ Printing Upgrade Underway at Yuengling!

America’s oldest brewery, D.G. Yuengling & Son, Inc., is making a smart move toward the future by upgrading to BestCode printing systems. This upgrade replaces aging and obsolete date coders across multiple production lines.

From date codes on the bottoms of cans, to reusable keg markings, to paperboard carton coding—Yuengling is investing in BestCode's modern, reliable coding technology that keeps up with the pace and precision of its operations.

✅ Simple. Affordable. Reliable.

✅ High resolution. Precision printing.

✅ Reduced maintenance.

✅ Greater production efficiency.

At a time when traceability and shelf-life accuracy matter more than ever, Yuengling’s investment in BestCode reinforces its commitment to quality and innovation.

Here’s to tradition meeting technology!

Trade Show News

BestCode Italy at iPack IMA in Milan

May 27–30, 2025

Visit the BestCode Mapi24 team in Pavilion 10, Stand E09-F10. Talk to the BestCode coding and marking experts about replacing your aging date coders with BestCode—simple, affordable and reliable printing systems designed for today’s production demands. Join the conversation. BestCode can help you improve uptime, reduce costs, and print with confidence.

In the Headlines

Coding and Marking Equipment Market to Grow by USD 1.46 Billion (2024-2028), Driven by Product Traceability Need and AI-Redefining the Market Landscape - Technavio

The global coding and marking equipment market size is estimated to grow by USD 1.46 billion from 2024-2028, according to Technavio. The market is estimated to grow at a CAGR of almost 6.89% during the forecast period. Increasing need for product traceability is driving market growth, with a trend towards deploying of equipment leasing business model. However, high operational costs poses a challenge. Key market players include ATD UK, BestCode, Brother Industries Ltd., Cyklop International, Danaher Corp., Diagraph, Dover Corp., Engage Technologies Corp., Hitachi Ltd., Illinois Tool Works Inc., Keyence Corp., Matthews International Corp., MULTIVAC Sepp Haggenmuller SE and Co. KG, Overprint Ltd., Paul Leibinger GmbH and Co. KG, Pro Mach Inc., REA Elektronik GmbH, RN Mark Inc., SATO Holdings Corp., Control Print Ltd, Domino Printing Sciences Plc; Markem-Imaje Group; Leibinger Group; REA Elektronik GmbH; Koenig & Bauer Coding GmbH; HSA Systems A/S.

Trade Show News

BestCode Brazil (Tesla) Showcasing Coding and Marking Solutions at Clean Fair Nordeste

March 20-21, 2025

The 5th CLEAN FAIR has come to an end, and we can only thank everyone who stopped by our booth, exchanged ideas, got to know our solutions in industrial coding and became part of this very special moment. It was a pleasure to be present at the largest chemical sector event in the Northeast and be able to share knowledge, technology and good conversations with so many amazing people.

Trade Show News

BestCode at Pack Expo Southeast in Atlanta

March 10-12, 2025

Meet with the BestCode team. Join the conversation with our experts D'Orlando Bolden, Ray Garcia and Sam Rankins. We’re showcasing the Quantum and Next Generation Series 8. Learn more about coding and marking solutions for your application challenges. Visit us in booth 532. Revolutionize your packaging lines with precision, speed, and reliability. Don’t miss out on the opportunity to discover the future of packaging innovation! BestCode is Simple. Affordable. Reliable.

News: BestCode in Action

Coding and Marking Solutions— Performance and Yield, Raise the Standard of your Production with Meat and Poultry Packaging Materials.

January 2024

It's time to replace your aging date coder. Upgrade to BestCode, the Future of Coding and Marking. BestCode's range of state-of-the-art date coders are designed to meet your production demands with ease. Whether you're in food & beverage, pharmaceuticals, or consumer goods, BestCode has a solution that delivers.

Trade Show News

BestCode Claudio at Marca by BolognaFiere

January 15-16, 2025

Join us at the 21st Edition Marca by BolognaFiere in Viale della Fiera, 20 40127 Bologna (BO). We’re thrilled to be showcasing our cutting-edge coding and marking solutions! Whether you’re in food, cosmetics, or any other industry, our coding and marking technology ensures precision, reliability, and efficiency in every product you make. See firsthand how we can help elevate your brand’s packaging, enhance traceability, and streamline your operations. Let’s make your products stand out with the best coding and marking technology on the market: the Series 8 Next Generation Coding and Marking and the Quantum—the Most Affordable Continuous Ink Jet Printer. It's time to replace your aging and obsolete date coders with BestCode. We can’t wait to connect with you!

News: BestCode in Action, Egg Production

BestCode Australia (Applied Industrial Printing Pty Ltd) a perfect match hatched for the egg farms of Victoria.

December 2024

In Victoria, Australia, the practice of coding and marking eggs is a key part of ensuring food safety, traceability, and meeting regulatory requirements. The egg industry in Australia is highly regulated, and marking eggs helps with identifying their source, production method, and handling.

Trade Show News

BestCode Canada (Weber Marking Systems Canada) at Advanced Design and Manufacturing Expo (ADM)

November 13-14, 2024

Join BestCode Canada in booth 2014, Palais des congrès de Montréal, Montréal, Québec, Canada. This is the perfect opportunity to dive into the latest in coding and marking solutions. Connect with industry leaders, explore innovative technologies, and share insights with fellow enthusiasts. Lower operating costs, lower cost of ownership. BestCode printing systems use less ink and require less maintenance than the competition. No Core. No expensive service contracts. Let us show you why it's time to replace those aging and obsolete date coders.

Trade Show News

BestCode at Pack Expo International in Chicago

November 3-6, 2024

What an amazing experience at PACK EXPO International in Chicago! We had an incredible time connecting with industry leaders, innovators, and professionals at one of the biggest trade shows of the year! The energy in the Windy City was electric. We’re so grateful for the opportunity to showcase our coding and marking solutions.

A huge thank you to everyone who stopped by our booth to chat, share insights, and explore new possibilities. Your support and enthusiasm are what make events like these so special! Looking forward to keeping the momentum going and building on the connections we made. Until next time, Chicago!

BestCode Brazil (Tesla) Showcasing Innovations at FISPAL Tecnologia

June 18-21, 2024

Visit with BestCode Brazil (Tesla) at FISPAL TECNOLOGIA in the São Paulo Expo Exhibition & Convention. See #BestCodeInAction. Test drive the Quantum—the most affordable CIJ system available built with rich operator functions in a space saving design.

BestCode Thailand (Wisebiz) at Propak Asia

June 12-15, 2024

Join BestCode Thailand (Wisebiz) in Bangkok, BITEC at booth E77. Explore #BestCodeInAction to see the "best in class" CIJ printing systems—Reliable. Simple. Affordable. We have solutions for your marking and coding applications. Connect with the team and join the conversation. See the full range of BestCode products. Test drive the Quantum—the most affordable CIJ printing system. Learn more about why it's time to replace those aging and obsolete date coders.

News: Quantum Launch

BestCode India (Finepack) at Quantum Launch in the US

June 20, 2024

Finepack is excited to be at the BestCode Quantum launch in the US! The new BestCode Quantum's high-speed printing is set to revolutionize product marking. With unparalleled precision and efficiency, it promises to enhance production lines and improve product traceability. Stay tuned for more updates and see how this advanced technology can transform your business!

News

BestCode Makes its Mark in Bergamo, Italy

May 22, 2024

This years’ annual BestCode European Sales Meeting was carried out in the inspirational city of Bergamo-Italy. With a demonstration of professionalism, constructive and successful collaboration—the meeting was a huge success.

Trade Show News

BestCode Ukraine (Promark) at IFFIP.

April 17-19, 2024

Join BestCode-UKRAINE (Promark) at IFFIP (International Forum of Food Industry and Packaging) in Stand 3A362. Visit with the Coding and Marking experts—see #bestcodeinaction. Explore Next Gen High Speed, High Resolution, Precision Printing with Series 8 and the Most Affordable CIJ Printing system with feature rich operator functions—the BestCode Quantum. It’s time to replace those aging and obsolete date coders. Eliminate downtime—BestCode offers self-support with BestCode Teaching Tools available 24/7. Update to the BEST coding and marking systems on the market. 📅 17 to 19 April, 2024, International Exhibition Center (IEC) 15 Brovarskyi Avenue, KYIV – UKRAINE 📍 Stand: 3A362

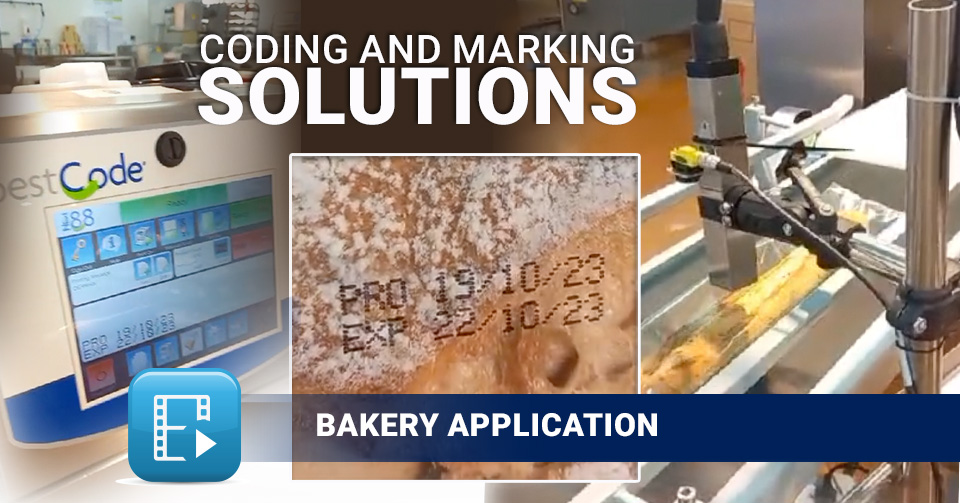

News: BestCode In Action, Bakery Applications

Quality and Control with BestCode Coding and Marking Solutions No manual code entry with BestCode AutoCoding Automation. Maintain your industry's product quality and control with BestCode Coding and Marking Solutions. Systems are fully programmable and have EcoTec™ Fluid Management making it the most efficient CIJ printer. Easily integrate into your existing production lines. No service contracts required with self-support options available 24/7—eliminating downtime. Try Before You Buy and In Plant Demonstrations are available. Let us show you why it is time to replace your aging, and obsolete date coders. Connect with the BestCode team in Booth 1030 at the Pennsylvania Convention Center March 18-20.

March 9, 2024

Trade Show News

Meet with the BestCode Team at Pack Expo East 24 in Booth 1030

February 10, 2024

Visit with the Coding and Marking experts at Pack Expo East in Philadelphia, booth 1030, March 18-20 at the Pennsylvania Convention Center. Explore ways to automate your process while increasing efficiency. Test drive the most affordable CIJ Printing system with feature rich operator functions—the BestCode Quantum. Register for free with our BestCode comp code 86K48.

News: BestCode in Action, Dairy Applications

BestCode Australia (Applied Industrial Printing Pty Ltd) in action.

January 23, 2024

BestCode Model 88 installed at ice cream plant in Melbourne. Look at the throw distance … easily 3 cm distance from printhead and printing beautiful. Cold room temperature, printing from bottom and printing on a wet ice cream tub.

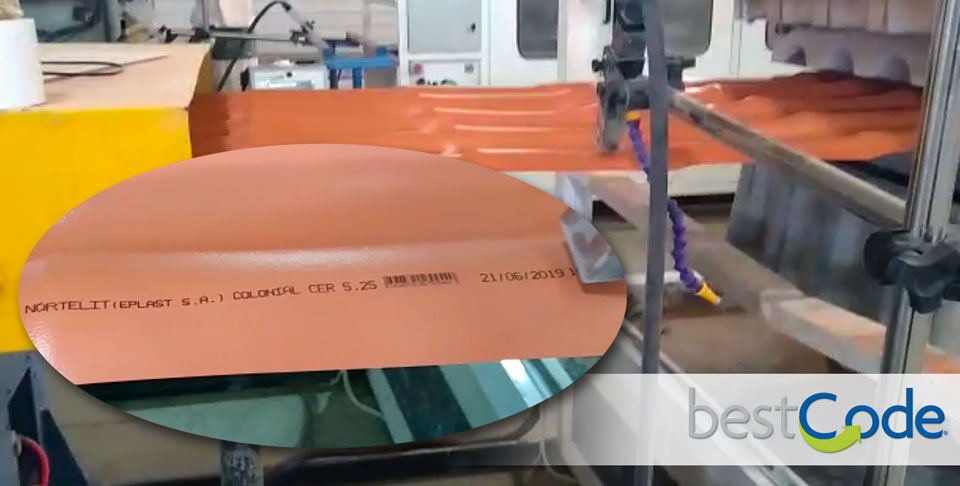

News: BestCode in Action, Flexible Packaging Applications

BestCode Ukraine (Promark) in action.

November 7, 2023

News: BestCode in Action, Bakery Applications

BestCode Puerto Rico (IGPR) at Bakery and Restaurant Show 2023

October 20 & 21, 2023

See BestCode Puerto Rico (IGPR) at the Asociación de Restaurantes de Puerto Rico (ASORE) Bakery and Restaurant Show October 20 & 21 in the Puerto Rico Convention Center. Learn more about coding and marking solutions for all your applications. BestCode Puerto Rico (IGPR) can show you why it's time to replace your aging and obsolete date coders. BestCode high speed, precision printing systems code and mark on any color substrates in a rainbow of colors—Yellow, White, Orange, Pink, Silver, Blue, Green, Red and more. Codes shine bright with high contrast inks featuring permanence and immediate dry time.

Trade Show News

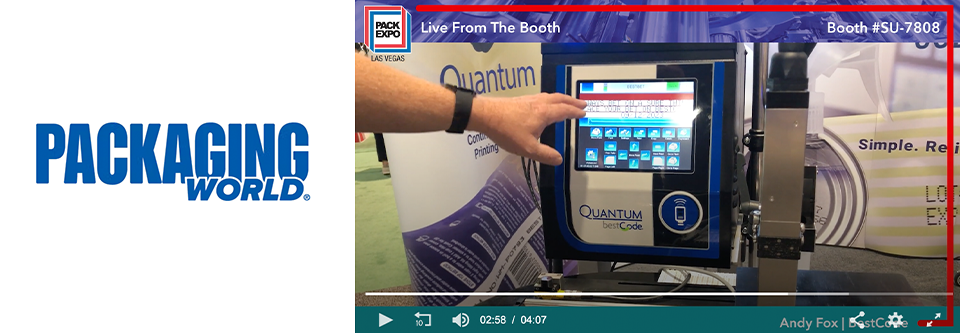

Low-Cost Small-Character Inkjet Printer

BestCode’s Quantum small-character CIJ printer offers simplicity and affordability for printing date and lot codes, sell by dates, and other identifying marks.

September 27, 2023

BestCode’s new Quantum continuous ink-jet printer (CIJ) provides a lower-cost alternative for small-character inkjet printing that offers many of the same features as the company’s more expensive stainless-steel, IP-rated unit.

Designed to print best by, lot, sell by, and expiration codes and other identifying marks on non-porous substrates, including plastic, metal, and glass, in real time, the Quantum can print one to five lines of text, barcodes, and graphics at 1,500 ft/min (for one line). Features of the Quantum include an AutoClean setting that automatically cleans the non-contact print head, OneTouch single-step operator functions that reduce operator steps, and on-the-fly external ink filling, for ink filling in less than a minute with no waste. Watch more...

News

BestCode at Pack Expo Las Vegas 23

September 11-13, 2023

CONNECT with BestCode at PACK EXPO Las Vegas, September 11-13 in booth SU-7808. Discover a Game Changer at South Upper Hall PACKage and Printing Pavilion. Attend for FREE with our BestCode comp code 36U93! Click below to register.

News

BestCode Brazil (Tesla Marcações Industriais) at Fispal Tecnologia 2023 São Paulo, Brazil

June 27-30, 2023

Thank you for joining the BestCode-Tesla Coding and Marking experts at Fispal Tecnologia in São Paulo, Brazil. We had a great show and demonstrated the NEW Quantum, the most affordable CIJ Printing system designed with feature rich operator functions and in a compact space saving enclosure.

News

Tesla BestCode at Fispal Tecnologia 2023 São Paulo, Brazil

June 27-30, 2023

Join the BestCode-Tesla Coding and Marking experts at Fispal Tecnologia in São Paulo, Brazil from June 27-30 at the São Paulo Expo Exhibition & Convention Center. Showcasing the NEW Quantum, the most affordable CIJ Printing system designed with feature rich operator functions and in a compact space saving enclosure. Join the conversation and discover Coding and Marking Solutions for your marking applications. BestCode systems have multiple operating languages, are designed for a global market and are the most efficient CIJ printer. Lower operating costs, lower cost of ownership. Environment friendly.

Trade Show News

BestCode Thailand (Wisebiz) at Propak Asia 23

June 14-17, 2023

Connect with BestCode at Propack Asia in Bangkok, Thailand! June 14 - 17. BestCode Thailand (Wisebiz) is presenting the new Quantum CIJ product — The Most Affordable Continuous Ink Jet Printing Machine and Series 8 machinery.

In the News

Top Food Processing Solutions Provider 2023

May 15, 2023

Awarded by Food & Beverage Technology Review

In the current packaging industry, the growing environmental concerns and demand for new products are pushing firms to leverage high-performance machines proven to deliver offerings that meet emerging client-specific requirements. Neway Packaging addresses this need through its unified portfolio of industry-leading packaging equipment and unmatched customizability. It distributes various machines used in the food industry with a portfolio combining packaging equipment from many leading vendors; Cousins Packaging, BestCode, Pack Leader USA, and PMI KYOTO. Using PMI KYOTO's innovative, high quality, and robust industrial packaging machines and equipment, Neway Packaging precisely meets customer specific needs, from simple case packing to full-line robotic integration.

Concurrently, its partnership with Cousins Packaging enables it to provide semi and fully-automatic machines that totally enclosed pallets of boxes and

cartons. Stretch wrapping pallets by Cousins Packaging allows for shipments to be shipped in a sanitary fashion. A solution-oriented partner, Neway Packaging offers cost-friendly packaging and labeling solutions for primary and secondary applications in the F&B industry. It boosts industrial wrapping, printing, coding, and marking processes across diverse F&B applications through its catalog of cutting-edge and reliable technologies. One of the most popular solutions in its marketplace is BestCode’s Model 88 CIJ Printer, which offers a wide range of dyes and soft-pigmented inks to help clients with necessary code dating and product identification printing. Read More...

Trade Show News

BestCode at Interpack 23

May 4-10, 2023

Great show at interpack 2023! BestCode Italy (TECNO srl) Pino and Fabio visit with Richard and Dennis. BestCode Italy (TECNO srl) announces complete support and software interface capabilities for wire and cable applications.

Connect with BestCode in Hall 15 D23-9. The show is open until May 10. Stop by and discuss Coding and Marking technology and commercial opportunities with Richard Fox and Dennis Sibley.

News

BestCode at Interpack 23

May 4-10, 2023

BestCode Tesla Marcações Industriais visit with Richard and Dennis at interpack 2023 - Processing and Packaging in Düsseldorf! Join us in Hall 15 D23-9. See #BestCodeInAction and connect with BestCode.

We're showcasing the NEW Quantum— the Most Affordable CIJ printing machine featuring rich operator functions in a compact space saving design. Don't forget your FREE print samples.

Meet with Richard Fox and Dennis Sibley. Let's discuss Coding and Marking technology and commercial opportunities.

News: BestCode in Action, Egg Grading

BestCode Australia (Applied Industrial Printing Pty Ltd) coding and marking solutions for egg production.

April 2023

Another successful and beautiful install by BestCode Australia (Applied Industrial Printing. Pty Ltd )in Melbourne, Australia.

News

High Speed. High Use Applications.

April 5, 2023

Let's talk about the BENEFITS of BestCode Industrial Ink Jet Systems:

1. High Resolution Precision Printing with Accuracy

2. Low Cost of Operation

BestCode systems use less ink and require less maintenance than the competition. No Core. No expensive service contracts. BestCode has Self-Support options available 24/7.

3. Versatility

BestCode systems can print on a wide variety of substrates including plastics, metals, glass, paper and more with a rainbow of high contrast and specialized inks.

4. Flexibility

BestCode systems integrate into existing production lines and can be used in a variety of applications

5. Speed

BestCode systems print at high speeds making them perfect for mass production and high volume printing

6. Last but certainly not least—Environment Friendly!

BestCode systems include EcoTec™ Fluid Management. Lower operating costs, lower cost of ownership. Learn more about BestCode print features here https://www.bestcode.co/print #bestcode in Ukraine

News

BestCode 88 CIJ Industrial Printer

March 15, 2023

Ink For Industry has the BestCode Model 88 in stock. Сучасні технології у маркуванні продукціі. Помірна вартість. Преміум якість.Обрати iFi - означає бути першим.

News

Special at TracePack on the BestCode 88 CIJ printer

February 10, 2023

Incredible special from TracePack on the BestCode 88 CIJ printer at just R69 000 ex VAT, fully installed; the price includes start-up ink and make-up, standard sensor and basic commissioning and training and a 3yr warranty. BestCode printing systems — Reliable. Simple. Affordable. If you would like to find out more about the BestCode 88 or would like to place your order, contact the TracePack sales team at 010 020 7221 or email

Trade Show News

Zutrad Ventures/BestCode at Propak West Africa

November 22-24, 2022

Zutrad Ventures/BestCode recently had a great show at Propak West Africa in Lagos, Nigeria. We enjoyed meeting with everyone to discuss Coding and Marking solutions for replacing your aging and obsolete date coders. BestCode systems are the most Reliable, Simple and Affordable. Precision crafted in the USA.

News

BestCode in Action Around the World

November 21, 2022

AutoJet/BestCode in Poland and Applied Industrial Printing Pty Ltd/BestCode in the Greater Melbourne Area. Automate your coding and marking process with high speed, high quality, precision printing. It's time to replace your aging and obsolete date coders. BestCode printing systems — Reliable. Simple. Affordable.

Check out our BestCode Series 8 printing systems and the NEW affordable Quantum.

News

BestCode launches the Quantum Continuous Ink Jet Printer as “The Most Affordable Continuous Ink Jet Printing System”

October 23, 2022

The Quantum is a high speed printing system capable to print 1 – 4 lines of text, barcodes and graphics. Print real-time “Best By”, “Lot Code”, “Sell By”, “Expiration Codes” and other identifying marks and codes to industrial and consumer goods to ensure product traceability. Print true non-contact, immediate dry, permanent, high speed, reliable marks and codes on a wide range of substrates, including plastic, glass, paper and more. A complete range of dye and soft pigmented inks are available in a variety of colors.

Systems feature BestCode’s AutoClean™ technology that automatically cleans the printhead routinely eliminating daily and weekly manual cleanings. BestCode’s large 10.4” Color Touch Screen is always on, providing a vivid display with large intuitive buttons and status indicators making the system easy to use. Employing OneTouch™ single step operator functions reduce operator steps eliminating mistakes. Ink is added On-the-Fly without print interruption in less than a minute with no waste. At the end of the day, the Quantum features - BestCode’s AutoOff™ Go Home Button automates and eliminates time consuming end of day manual date coder routines. “Go Home Button” means press the Power Off button and go home – the system self-cleans itself and powers the unit to an off state, ready to be started the next day.

The Quantum is enclosed in a “Built-to-Last”, Industrial, Galvanized Metal Powder Coated Enclosure. The system is a compact, lightweight space saving design. Durable, Precision Crafted IP55 rated enclosure allows long term, reliable operation in all sorts of wet, dry, dusty, hot or cold applications.

Designed for the world market the Quantum features more than 20 operation and print languages including all Latin based languages, Chinese, Arabic, Cyrillic, Korean, Thai, Vietnamese, Greek, etc. Systems utilize the Unicode character set with capabilities to print over 65,000 different characters and symbols.

News

BestCode at Pack Expo International in Chicago

October 23-26, 2022

BestCode released the new Quantum, the most affordable continuous ink jet system, and exhibited a complete range of BestCode coding and marking solutions from entry level affordable options through high end specialized engineered applications at the Pack Expo International in booth 4147. Thanks for joining the conversation and learning more about Coding and Marking Solutions for your applications. It was a great show in Chicago.

News

AutoJet BestCode in Poland

October 13, 2022

Automate your coding and marking process with high speed, high quality, precision printing. It's time to replace your aging and obsolete date coders. BestCode printing systems—Reliable. Simple. Affordable.

News

10 Tips For Buying Coding/Marking Equipment For Cases And Pallets

The handling of cases hasn’t changed, but the information required on the cases has. This is driven by documentation concerns (i.e., traceability) and the growing realization that all space is marketing space; so cases, once considered “Brown Boxes”, are now being leveraged to display corporate branding. Corrugated cases are moving closer to primary packaging. Also, ink-jet technology has improved considerably. Connectivity and footprints are smaller, and machines are easier to use. There are common touchscreen interfaces, levels of control, and higher resolutions. Instead of bottles of ink that you turn upside down, today’s technology features self-sealing cartridges and meters for easy visual checks. Here are some best practices to follow...

News

BestCode/Master Technologies at ITIF Asia the 18th International Trade and Industrial Fair

August 24, 2022

BestCode/Master Technologies exhibited a complete range of BestCode coding and marking solutions from entry level affordable options through high end specialized engineered applications at the 18th International Trade and Industrial Fair August 24-26. Thanks for joining us at the Karachi Expo Centre in Pakistan.

News

Replace your Aging and Obsolete Date Coders

July 20, 2022

One more satisfied customer from the food industry. BestCode Ukraine replaces old Linx 4900 with the new BestCode.

News

Tesla BestCode at Fispal Tecnologia 2022 São Paulo, Brazil

June 21-24, 2022

Thanks for joining the Tesla BestCode Coding and Marking experts at Fispal Tecnologia in São Paulo, Brazil from June 21-24 at the São Paulo Expo Exhibition & Convention Center. The show was a great success. We had many presentations showcasing solutions for marking and coding applications. BestCode systems have multiple operating languages, are designed for a global market and are the most efficient CIJ printer. Lower operating costs, lower cost of ownership. Environment friendly.

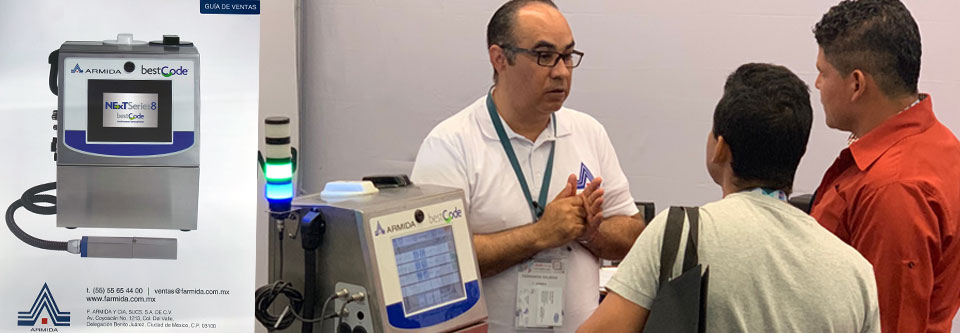

News

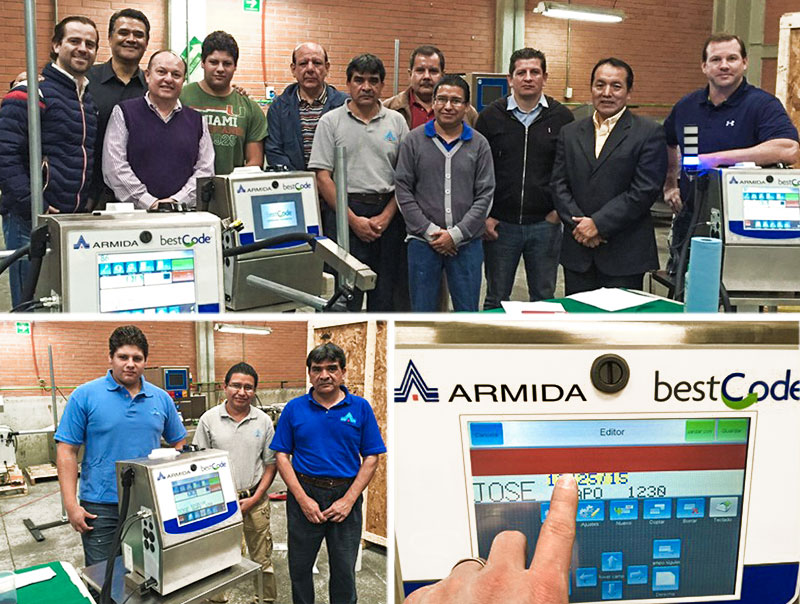

Armida BestCode at Expo Pack Mexico 2022 Mexico City, Mexico

June 14-17, 2022

Thanks for joining the Armida BestCode Coding and Marking experts at Expo Pack Mexico, Mexico City from June 14-17 in booth 1940. BestCode Armida’s Coding and Marking Experts discussed solutions for your aging and obsolete coders. BestCode systems are easier to use, have self-support options and more affordable operations. The show was a great success! Learn more about self-support with BestCode's Teaching Tools. BestCode has No Core Required, No Contracts and No Service Visits.

News

BestCode at Asia Pharma Expo 2022 Bangladesh

May 19-21, 2022

Thanks for joining the BestCode/US-BD Technology Ltd. Coding and Marking experts at the 13th ASIA Pharma Expo in Dhaka, Bangladesh from May 19-21 at the ICCB. The show was a great success. We showed many benefits for replacing your aging or obsolete coding systems. BestCode has the solutions for all of your Marking and Coding challenges. Self-support with BestCode Teaching Tools. Take control of your production line.

News

Join BestCode at Pack Expo East 2022 and meet with the BestCode team in Philadelphia, PA

March 21, 2022

BestCode is at Pack Expo East in Philadelphia, PA at the Pennsylvania Convention Center. Meet us in Booth #1218. Learn the benefits for replacing your aging or obsolete coding systems. We have the solutions for your Marking and Coding challenges.

News

Real Applications. Real Solutions.

January 2022

"The team at BestCode are quick to respond to our needs with parts, supplies, machines and service." Ryan Simpson, Operations Manager at Shield Packaging Co., Inc. in Dudley MA. BestCode systems are simple to operate with the easy-to-use large color Graphical User Interface. Eliminate rejects, recalls and fines with BestCode's high-speed precision print quality.

Replace your aging and obsolete date coders. BestCode has try-before you-buy and in plant demonstrations available. Ensure BestCode is the right machine for your application. Evaluate your options before your aging date coder is unrepairable.

News

Real Applications. Real Solutions.

January 2022

Dean McLeod, Production Manager from Lighthouse Brewery, Victoria, B.C. knows BestCode has the right Coding and Marking solutions for his company. "As a 20+ year craft brewing veteran, the BestCode printer is by far the best CIJ printer I have ever used. Print quality, reliability and ease of use are lightyears better than the old VideoJets I grew up on." Maximizing availability and uptime, no service contracts required with self-support options available.

Replace those aging, obsolete date coders. BestCode has try-before you-buy and in plant demonstrations available. Ensure BestCode is the right machine for your application. Evaluate your options before your aging date coder is unrepairable.

News

Join BestCode at Pack Expo East 2022 in Philadelphia, PA

January 28, 2022

BestCode will be at Pack Expo East March 21-23 in Philadelphia, PA at the Pennsylvania Convention Center. Meet us in Booth #1218. Learn the benefits for replacing your aging or obsolete coding systems. We have the solutions for your Marking and Coding challenges. Call today +1.817.349.8555 or email

We are offering FREE registeration to Pack Expo East by using our special comp code 54D28. Click the link to sign up today.

News

BestCode Coding and Marking Solutions—Extreme Industrial Coding and Marking in Mortar Manufacturing

December 13, 2021

Large character printing for easy reading when on pallet rack at distribution or retail locations. Imaging up to .75” (19mm) height. Precision print quality eliminating recalls, rejects and fines. Reliable—maximizing availability and uptime. Factory Air and Misting Systems available for dusty environments—eliminating dust, moisture and oil from entering the cabinet or printhead.

Replace those aging, obsolete date coders. BestCode has try-before you-buy and in plant demonstrations available. Ensure BestCode is the right machine for your application. Evaluate your options before your aging date coder is unrepairable.

News

BestCode at Pack Expo Las Vegas

September 29, 2021

See #BestCodeInAction LIVE at PACK EXPO Las Vegas in booth N-9806. Day 3 and we've got the Coding and Marking experts right here to show you SOLUTIONS for your marking and coding challenges. Stop in and say "hello". Evaluate BestCode options and replace that aging and obsolete date coder before it's too late.

News

BestCode featured in Packaging World Showcase

September 22, 2021

Hot Off the Presses! BestCode in Packaging World Showcase, Pack Expo Las Vegas show preview. We're packing up and getting ready to meet you all LIVE in Las Vegas at Pack Expo 21. This is your chance to meet with the BestCode team, your coding and marking experts. It's been a while and we have missed you. There's a lot to show! Meet the team in booth N-9806 and see #BestCodeInAction.

News

BestCode at Pack Expo Las Vegas

September 10, 2021

LIVE at Pack Expo Las Vegas September 27-29, 2021 in North Hall Booth 9806. Meet with the BestCode team, the Coding and Marking experts who have solutions for all your coding and marking challenges. PACK EXPO Las Vegas is the most comprehensive Packaging and Processing event in 2021.

Register for free using our complimentary code 91T51. LIVE at #PACKEXPO Las Vegas September 27-29, 2021 in North Hall Booth 9806. PACK EXPO Las Vegas is the most comprehensive Packaging and Processing event in 2021.

News

Better Brews—Ensuring Freshness with Marking and Coding

September 1, 2021

While the marking and coding arm of the packaging industry isn’t necessarily as alluring as its counterparts, it is undeniably important. This bit of variable data is essential to tell a history of a product, including batch codes, bottled on, and best-by dates. The food and beverage industry relies on marking and coding systems as part of the packaging and bottling process, no matter the size of the company. Established in 1996, Wild Onion Brewery is a family-owned craft brewery located just outside of Chicago, IL in Lake Barrington. The craft brewer has transformed from a half-barrel garage operation at its start to a multi-location, 50-barrel system brewer complete with canning capabilities

The brewery is constantly improving its operations. This includes the addition of a BestCode continuous inkjet system from Weber Packaging Solutions to its canning process. The device is used right after the cans leave the filler, a “packaged by” date is added to the bottom edge of the cans......[read more]

News

BestCode at IFFIP International Forum of Food and Packaging Industry

June 3-5, 2021

See BestCode in action at IFFIP International Forum of Food Industry and Packaging in Kiev, Ukraine June 3-5, 2021. Meet the Coding and Marking experts who have solutions for all your coding and marking challenges.

News

Automate Your Process with BestCode Coding and Marking Solutions

May 24, 2021

AutoCodes Eliminate Manual Date Code Entry. Automatically update born on dates, Best By dates and any other coding requirements. Print prior to filling or after the filling process. Alcohol Resistant Inks—resist wash away due to spillage. Inks for cold fill applications—penetrate thin layer of condensation. Learn more about Self-support options. Factory training available. No Contracts required. Systems are Reliable, Simple and Affordable. Watch the video.

News

Automate your High Speed—High Use Coding and Marking Applications with the BestCode Model 88S System

April 27, 2021

This model is typically used in high speed bottling applications such as large breweries and soda manufacturing. A complete range of dye and soft pigmented inks are available. BestCode also offers specialized inks for bottling applications including caustic washable inks for glass and plastics. Learn more about Self-support options. Factory training available. No Contracts required. Systems are Reliable, Simple and Affordable. Watch the video.

News

Mark and code anything with BestCode's Model 86 designed for the global market.

February 25, 2021

The possibilities are endless. Print real-time Best By, Lot Code, Sell By, Expiration Codes, Datamatrix, logos and other identifying marks to any substrate. Mark and code anything with BestCode's Model 86 designed for the global market. Systems are fully programmable. Automate your process and eliminate costly mistakes due to human error. Eliminate downtime with BestCode's self-support options. No waiting for service calls or paying for costly contracts. True non-contact printing. Inks dry immediately and are permanent. Learn more about Self-support options. Factory training available. No Contracts required. Systems are Reliable, Simple and Affordable. Watch the video.

News

BestCode Celebrating 10 Years

January 29, 2021

The BestCode group is proud to announce the 10 year anniversary of BestCode, producers of industry changing, forward thinking innovative industrial printing designs. Product designs are focused on ease of use, trouble free operation, long term reliability, and affordable cost of ownership with an emphasis on global market requirements. BestCode products are sold and serviced through a world-wide network of factory authorized, trained and certified distributor partners.

News

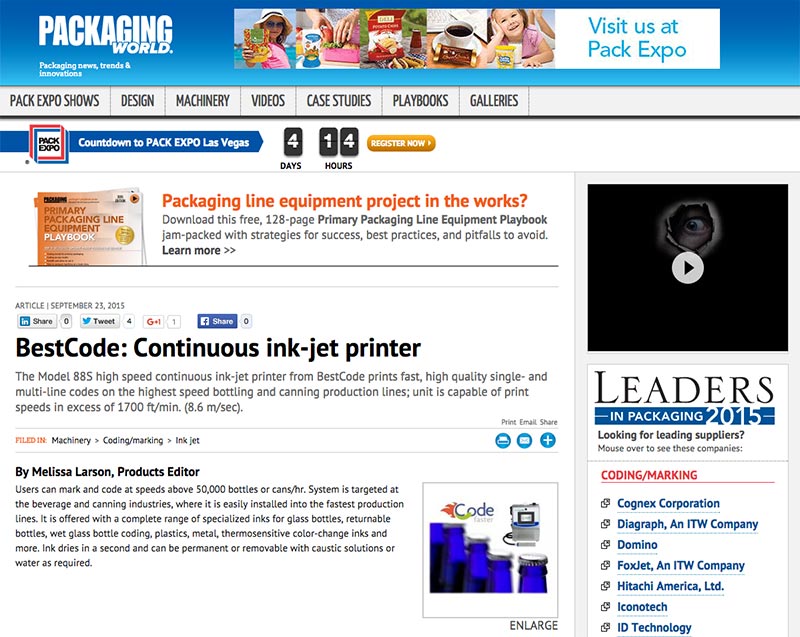

BestCode in Packaging World Leaders in Packaging 2021 Issue

January 10, 2021

See BestCode in Packaging World — Leaders in Packaging 2021. BestCode has self-support options and factory training available. No Contracts required. Systems are Reliable, Simple and Affordable.

News

Ultra High Speed Coding and Marking — 80,000 bottles per hour

November 20, 2020

Use BestCode Model 88 High Speed and 88S High Speed One in Ultra High Speed Bottling Applications. Print direct to glass and plastic with immediate dry time. Exceptional print quality at high speeds. Increase production and reduce downtime with BestCode Self-support options. The Model 88S High Speed is targeted at higher speed, high use applications, printing 1, 2 or 3 lines of text, barcodes or graphics. This model typically is used in high speed bottling applications such as large breweries and soda manufacturing.

News

Join BestCode at PackExpo Connects — Visit the Showroom

November 12, 2020

Learn how you can self-support with BestCode products and eliminate paying for service contracts. For 25 years, the BestCode group has continued to produce industry changing, forward thinking innovative industrial printing designs. Product designs are focused on ease of use, trouble free operation, long term reliability, and affordable cost of ownership with an emphasis on global market requirements.

News

Meet Packaging Laws. Print warning direct to trash bags.

September 21, 2020

Five U.S. states have regulations on suffocation warnings for certain plastic bags and each state's regulations and statutes specify the warning statements to be used. Meet packaging laws with BestCode. Systems can print Trash Bag Suffocation Warnings direct to Plastic Trash Bags. Print at high speeds with imaging up to .75” (19 mm). A variety of ink colors are available for contrasting print on white, black or other color trash bags. Ink Colors are available in Yellow, White, Black, Red, Blue, Green, Orange, Silver/Gray, Pink and more.

News

BestCode Coding and Marking Solutions for Bakery Applications

September 1, 2020

The BestCode Model 86 is targeted at high speed applications, printing 1, 2, or 3 lines of text, barcodes and/or graphics. This bakery application shows twin line date and lot coding. Ink dry time is within one second. BestCode has specialty inks for permanent adhesion to plastics.

News

BestCode Coding and Marking Solutions: Dairy, Milk Industry

August 27, 2020

BestCode's Model 86 printer coding and marking yogurt, ready-to-eat cups individually printed with manufacturing date and "best before" date codes. Features include traverse coding and marking capabilities built-in as standard on all BestCode models. Specialized inks for cold fill applications with Fast-Dry feature. Inks are capable of penetrating a thin layer of condensation with excellent adhesion and adheres to waxy / greasy substrates (such as materials used in the juice and dairy industries). BestCode inks provide excellent resistance to condensation that can occur during the refrigeration process. Print plastic, Tetra Paks, metal, glass (returnable and non-returnable), coated paper stock, PET bottles, and Polyolefin caps. BestCode has self-support options, factory training available and no contracts required.

News

BestCode Industrial Coding and Marking Solutions

July 29, 2020

BestCode Model 81 coding and marking solutions for industrial applications. BestCode's Model 81 is a reliable, simple, affordable entry level system. Real-time coding—information is updated to the second. Immediate dry inks. Print text, graphics and barcodes in a variety of colors. High, visual ink for easy reading by consumer. Systems provide 24/7 — 365 marking and coding operations. Want to see more? See application videos from the field.

News

BestCode in Packaging World Special COVID-19 Issue

May 31, 2020

BestCode has been open and operating as an essential supplier during these changing times to support your coding and marking operations. New machines are available to replace machines that are unable to be serviced. Call or email for pricing and trade opportunities.

News

BestCode-Weber and Wild Onion—Read something nice today: The slow, steady, sustainable story of Illinois’ Wild Onion Brewery

May 13, 2020

What was once farmland and an abandoned quarry has

become a small piece of paradise in the northwest Chicago suburbs. Wild Onion Brewery is one of Chicago’s first craft breweries of the modern era, firing up their first batch of Paddy Pale Ale in 1996. Family-owned, and located just off Route 14 in Lake Barrington, IL, this small but mighty brewer has seen steady, well-managed growth for over 23 years.

With roots going back to the Kainz family dairy business in Chicago in the early 1900s, founding brewer Mike Kainz had always been intrigued by family brewing stories. His grandfather and uncles had converted part of their dairy to beer production on the sly during Prohibition to keep thirsty Chicagoans happy in the 1920’s. There were stories of fermenting beer in stainless steel milk tanks and rolling barrels down the alley behind the dairy at night.

One of their recent equipment additions is a BestCode continuous ink jet system from Weber Packaging. Installed right after the cans leave the filler, a “Packaged by” date is added to the bottom edge of the can. It is especially important for brewers to have this information on all their products to ensure that only fresh products are distributed to stores and venues. Brewers know that some beers are shelf-stable for longer periods of time than other beers. If a customer gets an out-of date beer and it tastes off, they might judge that all your beers are like this one. It pays to keep things fresh and tasting their best....[read more]

News

BestCode C&E webinar presenting BestCode with Andy Fox, BestCode Business Development Manager.

April 20, 2020

Watch and learn more about BestCode and the Series 8 product line. Reliable. Simple. Affordable. Entry level affordable options, through mid-range capabilities and high end, specialized engineered solutions focusing on the highest speed, most sophisticated applications.

News

BestCode Operating as an "Essential Supplier" to support Coding and Marking Operations Worldwide

March 15, 2020

BestCode Coding and Marking Solutions. Open and operating to support your Coding and Marking operations. NEW machines are available to replace machines that are unable to be serviced. Call or text +1.413.813.8170 for pricing and trade in opportunities. Email also available,

News

Innovative Supply Side Company in the Packaging Community Packaging World's Leaders in Packaging 2020

January 28, 2020

See BestCode in Packaging World's Leaders in Packaging 2020. The program is now a Packaging World institution.

BestCode offers a complete range of marking and coding solutions (50+ model configurations) — entry level affordable options through mid-range capabilities and high end, specialized engineered solutions focusing on the highest speed, most sophisticated applications. A broad range of inks are available to meet the demands of any industrial printing application.

Products are designed and manufactured in the USA; Fort Worth, Texas. For more than 25 years, the BestCode group continues to produce industry-changing, forward-thinking innovative industrial printing designs. Product designs are focused on ease of use, trouble-free operation, long-term reliability, and affordable cost of ownership with an emphasis on global market requirements.

Specialized solution systems include High Speed and Super High Speed options for print applications in excess of 1700 feet per minute (8.6 meters per second) for the highest speed bottling/canning and wire/cable applications. Print capabilities include White Pigment/Opaque inks for dark-colored substrates, Food Grade options for direct to food printing, Micro printing for high-resolution and micro/small-character applications. Systems feature USB, Ethernet (DHCP), RS232 and multiple programmable inputs/outputs for control via PC, Web Browser, HMI, PLC, network, etc.

BestCode, a 2020 Leader in Packaging, will be at InterPack 2020 from May 7-13 in Düsseldorf, Germany. Visit with the experts in Hall 12 C66-7. We have FREE test prints and solutions for your coding and marking challenges.

News

Accurate coding and marking in extreme environments

October 25, 2019

Watch BestCode in action. High speed Coding and Marking designed for the global market. Reliable. Simple. Affordable. Entry level affordable options, through mid-range capabilities and high end, specialized engineered solutions focusing on the highest speed, most sophisticated applications.

News

BestCode at PACK EXPO Las Vegas 2019 - Visit Booth C-5117

September 23-25, 2019

BestCode has the Coding and Marking Solutions. Reliable Simple Affordable. Meet with us in booth C-5117 at PACK EXPO Las Vegas Central Hall — PACKage Printing Pavilion. We're producing industry changing, forward thinking, innovative industrial printing designs with Self-Support Options & Factory Training available — No Contracts Required. BestCode Coding and Marking Solutions.

News

BestCode at PACK EXPO Las Vegas - Plan your show experience, BestCode featured in Packaging World's Showcase Planner

September 18, 2019

Check out the “best of” PACK EXPO Las Vegas in Packaging World's 2019 SHOWCASE—the official pre-show planner. BestCode, 2019 Leader in Packaging, will be located in booth C-5117. Visit with the experts and pick up your FREE test prints.

BestCode Marking and Coding Solutions: Reliable. Simple. Affordable. BestCode industrial printing systems print real-time lot/date, sell-by dates, expiration dates and other identifying marks on industrial and consumer goods to ensure product traceability. BestCode Products are designed and manufactured in the USA; Fort Worth, Texas. For 25 years, the BestCode group continues to produce industry changing, forward thinking innovative industrial printing designs. Product designs are focused on ease of use, trouble free operation, long term reliability, and affordable cost of ownership with an emphasis on global market requirements. BestCode offer a complete range of industrial printers for marking and coding solutions (50+ configurations) - entry level affordable options, through mid-range capabilities and high end, specialized engineered solutions focusing on the highest speed, most sophisticated applications. Systems feature USB, Ethernet (DHCP), RS232 and multiple programmable inputs/outputs for control via PC, Web Browser, HMI, PLC, network, etc. BestCode products are sold, serviced and supported in more the 70 world markets. - Self Support Options Available. - Factory Training Available. - No Contracts Required. See BestCode products in action - Central Hall — C-5117 — PACKage Printing Pavilion....[read more]

News

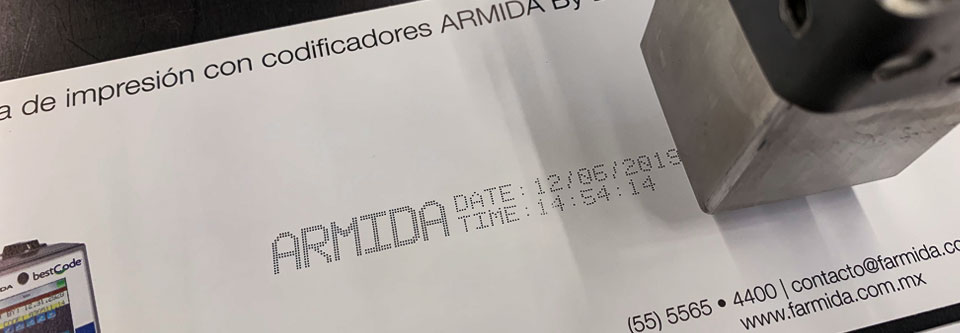

BestCode-Armida Coding and Marking Solutions Designed for the Global Market

August 22, 2019

Watch BestCode in action. BestCode offers a complete range of industrial printers for marking and coding solutions (50+ configurations) - entry level affordable options, through mid-range capabilities and high end, specialized engineered solutions focusing on the highest speed, most sophisticated applications.

News

Tesla-BestCode at 60th Bastos Egg Fest 2019 – São Paulo, Brazil

July 18-20, 2019

See BestCode in action at the Kisuke Watanabe Exhibition Center. Coding and marking experts are on hand to present the newest and best coding and marking solutions for traceability in eggs. The festival is the biggest event of the Brazilian commercial poultry since the pioneering years of the poultry industry of the Egg Capital. The event hosts poultry farmers, technicians and representatives of companies that supply all the production centers of the country. Coding and Marking Solutions. Reliable. Simple. Affordable.

News

BestCode-Weber: Wild Onion Brewery - A Family Brewing Tradition

July 17, 2019

What was once farmland and an abandoned quarry has

become a small piece of paradise in the northwest Chicago suburbs. Wild Onion Brewery is one of Chicago’s first craft breweries of the modern era, firing up their first batch of Paddy Pale Ale in 1996. Family-owned, and located just off Route 14 in Lake Barrington, IL, this small but mighty brewer has seen steady, well-managed growth for over 23 years.

One of their recent equipment additions is a BestCode continuous ink jet system from Weber Packaging. Installed right after the cans leave the filler, a “Packaged by” date is added to the bottom edge of the can. It is especially important for brewers to have this information on all their products to ensure that only fresh products are distributed to stores and venues. Brewers know that some beers are shelf-stable for longer periods of time than other beers. If a customer gets an out-of date beer and it tastes off, they might judge that all your beers are like this one. It pays to keep things fresh and tasting their best....[read more]

News

High Speed Coding and Marking—Date Coding

June 28, 2019

Watch BestCode in action. Print and adhere permanently to HDPE, LDPE, PE — any plastic or rubber substrates. Multiple line print capabilities. TRUE NON-contact printing—up to 2” (50mm) ink throw distance. Inks are available in a rainbow of colors.

News

Tesla-BestCode at Fispal 2019 – Sao Paulo Expo

June 25-28, 2019

See BestCode in action and visit with your BestCode-Tesla Coding and Marking experts in booth M182. Get your FREE test prints and see the difference. The Closer you Look, the Better BestCode Looks. Systems feature more than 20 operational languages and print capabilities with true non-contact FreakyFast™ printing.

BestCode: Reliable, Simple, Affordable. IP65 rated. Extreme environment friendly. Talk with the experts about solutions for all your coding and marking challenges.

News

BestCode 88S Opaque system

June 24, 2019

Watch BestCode in action printing with White Acetone Ink direct to rubber material. Immediate ink dry time and permanent adherence. Model 88S Opaque is typically used in high speed wire and cable applications as well as PVC pipe extrusion, automotive parts, cosmetics and other dark colored substrates. Print in a variety of colors — White for dark colored substrates and Light Blue, Aqua Blue, Silver/Gray and Pink allowing printing on dark and light colored substrates with one system.

News

BestCode-Armida at ExpoPack 2019

June 13, 2019

See #BestCodeInAction. Pick up your Free test Prints and get BestCode on the call list for all your marking and coding challenges. 📞 817.349.8555

News

Armida-BestCode at ExpoPack 2019 – Guadalajara, Mexico

June 11-13, 2019

See BestCode in action and visit with your BestCode Coding and Marking experts in booth 2150. Get your FREE test prints! The closer you look, the better BestCode looks. Systems feature more than 20 operational languages and print capabilities with true non-contact FreakyFast™ printing.

BestCode: Reliable, Simple, Affordable. IP65 rated. Extreme environment friendly. Talk with the experts about solutions for all your coding and marking challenges.

News

BestCode prints real-time "Best if Used by" information direct to packaging. Systems are IP65 rated, extreme environment friendly.

June 7, 2019

Phrases like "Best By", "Enjoy By" and "Fresh Through" generally indicate when a food's quality would decline — not when it becomes unsafe to eat. To help make that clearer, the U.S. Food and Drug Administration recently recommended ...[read more]

News

BestCode Coding and Marking Solutions – Designed for the Global Market

June 6, 2019

High use. High speed applications. BestCode in action: Coding and Marking Solutions. Reliable. Simple. Affordable. IP65 rated. Get BestCode on the call list for all your marking and coding challenges. 📞 817.349.8555

News

BestCode prints real-time "Best if Used by" information direct to packaging

May 28, 2019

What does "best if used by" on packaged food really mean? When it comes to labels on food, there's no agreed upon wording to let consumers know when to toss packaged grocery items. Public confusion over how long they can keep and safely eat products is part of the reason Americans throw away roughly a third of their food — about $161 billion worth — each year. The FDA is backing a uniform label to show when a product's quality might start to fade...[read more]

News

BestCode Coding and Marking Solutions – Coding on Glass. High Contrast. Yellow.

April 19, 2019

BestCode has made Series 8 systems the benchmark for Continuous Ink Jet Printers. Everything from the Series 8’s industrial IP65 rated exterior to the ease of use OneTouch™ interface, AutoOff™ Go Home Button and high speed performance have been engineered to make Series 8 products, the BEST! Click here for more information about BestCode inks. Get BestCode on the call list for your marking and coding challenges 📞 817.349.8555

News

BestCode Coding and Marking Solutions – Reliable. Simple. Affordable.

April 12, 2019

BestCode in action: Coding and Marking Solutions. Reliable. Simple. Affordable. IP65 rated. Get BestCode on the call list for all your marking and coding challenges. 📞 817.349.8555

News

Representaciones Industriales at HonduExpo Packaging and Design 2019 – San Pedro Sula, Honduras

April 2-4, 2019

See BestCode in action and visit with your BestCode Coding and Marking experts in Stands 79, 80, 81, 82. Reliable, Simple, Affordable. Extreme environment friendly. Systems feature more than 20 operational languages and print capabilities with true non-contact FreakyFast™ printing. Talk with the experts about solutions for all your coding and marking challenges.

News

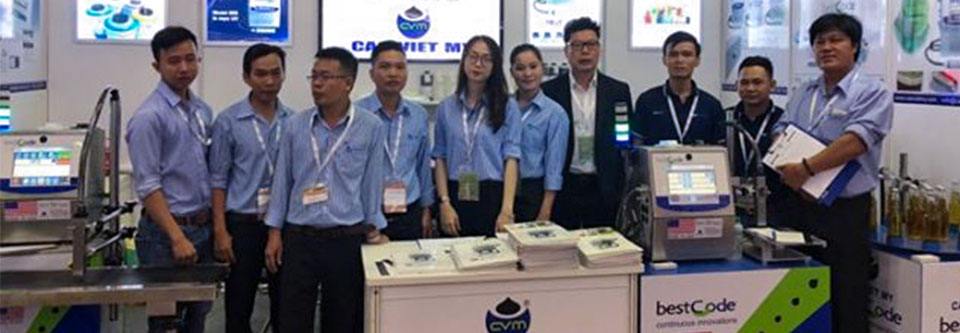

Cao Viet My at ProPak Vietnam 2019 – Ho Chi Minh City, VietNam

March 19-21, 2019

Cao Viet My - BestCode Coding and Marking specialists exhibiting in Booth A7 Hall A. Showcasing a complete range of small and large character industrial printing systems. Reliable, Simple, Affordable, IP65 rated and extreme environment friendly.

Series 8 continuous ink jet printers print high speed, reliable lot / date, sell-by date, best if used by, best before and other identifying marks and codes on a wide range of substrates including plastic, glass, paper, metal and more. Simple — OneTouch™ the 10.4” color LCD touch interface. Multiple operating languages designed for a global market. Affordable — with EcoTec™ Fluid Management, the most efficient continuous ink jet (CIJ) printer. Lower operating costs, lower cost of ownership. Environment friendly inkjet coding solution. Reliable — Maximized uptime with a 40,000 hours MTBF (mean time between failure) rating, backed by a two year manufactures warranty CodeProtect™ and one year scheduled maintenance, built-in. #BestCodeInAction around the world.

News

Weber Packaging Solutions at WestPack 2019 – Anaheim, CA

February 5-7, 2019

Join Weber Packaging - BestCode your Coding and Marking experts in Booth 5039. Reliable, Simple, Affordable. Extreme environment friendly. Systems feature more than 20 operational languages and print capabilities with true non-contact FreakyFast™ printing. Talk with the experts about solutions for all your coding and marking challenges.

News

Master Technologies at Pak Pharma & Healthcare 2019 – Lahore, Pakistan

January 15-17, 2019

Master Technologies - BestCode Coding and Marking specialists in Stand E14 Hall 1. A complete range of small and large character date coder printing systems. Reliable, Simple, Affordable. Minimize user interaction. Operate multi-weeks/months between adding fluids. Large fluid operating capacities. Systems feature more than 20 operational languages and print capabilities with true non-contact FreakyFast™ printing. Talk with the experts about solutions for all your coding and marking applications and challenges.

News

SmartSystem at Apex Cairo 2018 – Cairo, Egypt

December 8-10, 2018

SmartSystem the local Egypt BestCode Coding and Marking specialists showcase BestCode Series 8 complete range of Continuous Ink Jet machines. Print Sharper, Crisper and Clearer. Visit and learn more about Performance, Innovation and the Craftsmanship you will find with BestCode's industrial printing systems. BestCode is the most efficient CIJ printer. Lower operating cost, lower cost of ownership.

News

Weber Packaging at PackExpo 2018, Chicago, IL

October 14-17, 2018

Learn More from Weber Packaging / BestCode your Coding and Marking specialists. Showcasing BestCode models 81, 86, and 88s. Print Sharper, Crisper and Clearer. Visit and learn more about Performance, Innovation and the Craftsmanship you will find with BestCode's industrial printing systems. BestCode is the most efficient CIJ printer. Lower operating cost, lower cost of ownership.

News

Canadian Packaging

Like a Walk in the Park — British Columbia brewer uses communal code of ethics to create a high-quality beer that fully connects to local roots and scenery

June 2018

by Andrew Joseph, Features Editor

After purchasing the brewhouse and all the requisite tanks, vessels, mixers, fermenters and other essential pieces of brewing equipment in the autumn of 2016, The Parkside Brewery invested in a brand new inkjet coder, the BestCode Model 82 printer from industry specialists Weber Marking Systems Canada, installed in October.

Payne says the inkjet coding system was a necessity to track product for date of production and quality control purposes as an essential part of food and beverage industries safety initiatives. "We apply date coding onto all our canned products;' says Payne. According to Weber Marking Systems account manager for Western Canada Jay Allen: "They chose to purchase from Weber because of our years of experience — we've been around for 85-plus years. Our longevity provided Parkside with the confidence that we are here to support them. "One of the reasons they chose the BestCode unit was because of the clarity and size of its 10.4 inch touchscreen display. The employees found it very easy to navigate, enabling them to make changes on the fly without any issues," continues Allen. Distributed by Weber throughout Canada, the BestCode model 82 industrial marking and coding system is a small-character printing system that provides high print speed, combined with reliable marking capabilities on the aluminum surface and a wide range of substrates such as plastic, glass, paper and more, according to Weber.

While the Series 8 from BestCode comes in six models: the 81, 82, 86, 87, 88, and 88S —

the Model 82 purchased by The Parkside Brewery provides:

- Extended operation time thanks to its robust design, capable of operating at speeds up to 600 feet (196 Meters) per minute;

- AutoOff™ Automated end-of-day routine which eliminates the typical manual routine;

- New levels of user simplicity;

- Abilities to print both small and large character information, as required by the customer;

- Capability for true non-contact printing that extends the ink throw distance;

- Increasing print speeds to ultra-high speed specifications, as required;

- CleanStart™ industrial stainless-steel printheads ready to use in one minute, shortening downtime. The CleanStart™ printheads feature a special system that eliminates annoying clogged nozzles;

- An interactive EZTouch™ 10.4 inch touchscreen display with intuitive icon buttons for easy use and a clear visual display of all operating information;

- The SmartFill™ ink system, allowing fluid addition on-the-fly without opening enclosure;

- The EcoTec™ fluid management system to reduce fluid consumption, contributing to a reduction in the overall cost-of-ownership.

The BestCode inkjet systems are designed and manufactured by Weber's partners in Forth Worth, Texas and include a complete range of marking and coding solutions from entry level options all the way to specialized applications that require high-speed solutions. The BestCode model 82 owned by The Parkside Brewery is designed, according to Weber, for basic applications. It is best utilized for target applications printing one or two lines of text, with one to two production line work shifts per day, five-days-per-week equating to upwards of 4,000 hours of annual operation. Payne says the brewery uses the BestCode Model 82 inkjet printer to apply a clean, black marking of lot code data to the lower lip of its can packages, although the adjustable printhead can be positioned to print anywhere on the package. "We currently run the BestCode Model 82 at a speed of about 30 cans per minute," says Payne, noting that the inkjet coder can operate faster should the need change. "As well, the BestCode 82 provides us with low ink usage and reliability, so there's no downtime on our filling and packing production line...

Read more online.

News

FISPAL 2018, Brazil

June 26-29, 2018

Learn More from Tesla Marcações Industriais / BestCode your Coding and Marking specialists at Fispal Tecnologia. Showcasing BestCode models 81, 86, and 88s. See BestCode In Action with the 88S Ultra High Speed Marking and Coding for Canning and Bottling Date Coding Applications. Print Sharper, Crisper and Clearer. Visit stand L171 and learn more about Performance, Innovation and the Craftsmanship you will find with BestCode's industrial printing systems. BestCode is the most efficient CIJ printer. Lower operating cost, lower cost of ownership.

News

Expo Pack 2018, Mexico

June 5, 2018

Talk with the Marking and Coding experts at EXPO PACK México. Visit booth 2536 and learn more about Performance, Innovation and the Craftsmanship you will find with BestCode's industrial printing systems. BestCode is the most efficient CIJ printer. Lower operating cost, lower cost of ownership. Environment friendly.

News

Hispack 2018, Spain

May 8, 2018

Visit BestCode at Hispack and meet with the marking and coding experts in Barcelona, Spain in Stand 712.

News

Laying the groundwork — A strong initial equipment foundation has this burgeoning Oklahoma brewery poised to take the next step.

April 3, 2018

By Matt Reynolds, Editor

Rivers, lakes, mountains, and forests don’t immediately leap to mind when you think of Oklahoma. But in the eastern part of the state, the town of Broken Bow sits adjacent to the sylvan Hochatown State Park, which houses a large reservoir fed by nearby mountain streams. For weekend warriors in cities like Tulsa, Oklahoma City, and Dallas, each about three hours away by car, this represents a refreshing change of scenery. And nothing fits better into a getaway-ready tourist town than a local brewery.

Recognizing this niche hadn’t been filled by 2015, now co-owners Mark McDaniel, Charles Wilson, and Keith Shearer decided they wanted to be the ones to bring a brewpub, complete with food and tasting room, to Broken Bow. Such was the genesis of Mountain Fork Brewery, the name owing itself to the pristine nearby river from which the company sources water for brewing.

“We started brewing on a 60-gallon system and serving out of the taproom,” says Keifer Shearer, General Manager, Mountain Fork. “But it didn’t take long for us to recognize that we were full of people every night. And people would constantly ask where in Dallas or Oklahoma City they could get our beer. We realized we needed to go bigger.”

In October 2017, the fledgling brewing company made the jump from a 60-gal system to a 20-barrel, 3-vessel system in a new facility, and management brought in talent that could manage the much larger setup. Peter Hemmingsen, a Dallas native, brewer, and recent graduate of the University of California-Davis brewing program, took over the reigns as brewmaster. Now, six months later, the company is hitting an inflexion point where the lion’s share of sales will soon be in markets outside of Broken Bow.

“Right now, most of our beer is still sold through our taproom. We’re lucky to have a huge following,” Hemmingsen says. “But we’re aiming be distributing in Oklahoma City by April, and then Tulsa is next. My ties are from Dallas, and we already have our Texas license; we need to get label approval for each of the individual beers, but in six months we plan on being in Dallas as well. For now, cartonized six-pack paperboard boxes will be the main distribution format.”

Canning line

The front half of the canning line represents one of the first installations in North America of Palmer Canning Systems’ Generation 2, 12/1 (12 filling nozzles, 1 seaming station) canning line. Within this turn-key setup, an overhead depalletizer single files cans and sends them through an inverter, opening them up to an ionized-air deduster. Unfilled cans then enter a BestCode inkjet date coder distributed by Weber Packaging Solutions. Next, cans enter the Palmer 12-head carousel filler and seamer. Cans travel around the carousel and are purged with CO2 prior to filling.

Read more online at Packaging World.

News

Serialization — BestCode Coding Security System

November 13, 2017

Invisible ink prints clear and invisible and can only be seen when fluoresced with UV light. The codes and marks light up a bright blue color. Printing is permanent to a wide range of substrates, drying immediately on metal, glass, plastic and more. Invisible codes survive high temperatures and remain invisible when exposed to high temperatures, steam processes such as that used for pasteurizations or sterilization processes. Read more online at Serialization.

News

Healthcare Packaging — BestCode Coding Security System

November 13, 2017

Model 88S for product security and counterfeit avoidance is print-invisible, UV light-readable. Read more online at Healthcare Packaging.

News

Packaging World — BestCode Coding Security System

November 10, 2017

By Melissa Larson, Products Editor

Users can print real-time one-dimensional (1D) and two-dimensional (2D) barcodes – Datamatrix, QR Code, and other custom dot codes on demand. Barcodes can be encrypted with company and product specific serialization information. Read more online at Packaging World

For Immediate Release

BestCode Introduces the:

Model 88S Security System

Print Invisible, UV Light Readable.

For Product Security and Counterfeit Avoidance.

November 10, 2017

The Model 88S Security is targeted at product traceability, security, counterfeit avoidance and brand protection applications. Ensure the product in question is truly your product.

Print Real-Time One-Dimensional (1D) and Two-Dimensional (2D) barcodes – Datamatrix, QR Code and other custom dot codes on demand. Barcodes can be encrypted with company and product specific serialization information.

Invisible ink prints clear and invisible – can only be seen when fluoresced with UV light. The codes and marks light up a bright blue color. Printing is permanent to a wide range of substrates – drying immediately on metal, glass, plastic and more. Invisible codes survive high temperatures and remain invisible when exposed to high temperatures, steam processes such as that used for pasteurizations or sterilization processes.

88S Systems are simplified to allow anyone to operate, minimizing operator touches, extending time between human interaction.

- CleanStart™—automatically cleans printhead eliminating daily and weekly cleanings.

- 10.4" Color Touch Screen—always on, vivid display with large intuitive buttons and status indicators.

- OneTouch™—single step operator functions reduce operator steps.

- Large Volume Ink Tanks—extend time between fluid additions to weeks or months.

- On-the-Fly External Ink Filling—accomplished in less than a minute with no waste.

- AutoOff™ Go Home Button—automate and eliminate time consuming end of day manual routines.

Designed for the world market the Model 88S Security features more than 20 operation and print languages including all Latin based languages, Chinese, Arabic, Cyrillic, Korean, Thai, Vietnamese, Greek, etc. Systems utilize the Unicode character set with capabilities to print over 65,000 different characters and symbols.

BestCode products are backed by CodeProtect™, the industry’s best coding system coverage.

Learn more at www.bestcode.co/model-88s-security

About BestCode: BestCode Products are designed and manufactured in the USA, Fort Worth, Texas. For 25 years, the BestCode group continues to produce industry-changing, forward-thinking innovative industrial printing designs. Product designs are focused on ease of use, trouble-free operation, long-term reliability, and affordable cost of ownership with an emphasis on global market requirements. BestCode is a member of PMMI (Packaging Machinery Manufacturer’s Institute) and Fort Worth Chamber of Commerce.

BestCode products are sold and serviced through a worldwide network of factory-authorized, trained and certified distributor partners. BestCode products are marketed and supported in over 80 world markets. For more information, visit www.bestcode.co (not .com).

News

PackExpo 2017, Las Vegas

September 27, 2017

Meet the Founders at PackExpo 2017 in Las Vegas, September 25-27 in booth S-6133.

News

PackExpo 2017, Las Vegas

September 26, 2017

Meet and learn from BestCode's Design and Engineering Team at PackExpo in Las Vegas, booth S-6133.

News

PackExpo 2017, Las Vegas

September 25, 2017

Meet and learn from BestCode's Design and Engineering Team at PackExpo in Las Vegas, booth S-6133.

News

BestCode Announces Membership in PMMI

August 25, 2017

PMMI connects the makers of goods with the packaging and processing suppliers they rely on. They provide people around the world with innovative, safe, convenient and cost-effective products that touch lives every day. PMMI advances the industry through their world-class PACK EXPO portfolio of trade shows, PMMI Media Group and a wide range of Business Drivers.

News

BestCode — Proud Member of the Fort Worth Chamber

August 25, 2017

The Fort Worth Chamber of Commerce is the premier business association in Tarrant County and the largest Chamber in North Texas.

News

Meet the BestCode Tesla Sales and Service Team

June 27-30, 2017

See BestCode in action — FISPAL 2017 in Brazil June 27-30, stand 140. The BestCode Tesla team—ready to sale, service and support your coding and marking applications. Stop by and see BestCode Series 8 products and demonstrations.

News

BestCode: Coder for extreme wet conditions

May 15, 2017

By Melissa Larson, Products Editor, Packaging World

The Model 88S Extreme coder is enclosed in a 316 grade stainless steel corrosion-resistant enclosure; system can be ordered with optional positive air system for enclosure and printhead, enabling the system to operate in the most extreme wet or high dust applications found in food and beverage manufacturing. Read more online at Packaging World.

For Immediate Release

BestCode Introduces the:

Model 88S Extreme System

SS316 Grade Stainless Steel Enclosure

For Extreme Wet and High Dust Protection

April 28, 2017

Print real-time “Best By,” “Lot Code,” “Sell by,” “Expiration Codes” and other identifying marks and codes to any substrate in the most extreme wet and high dust environments.

The Model 88S Extreme is enclosed in a 316 Grade Stainless Steel corrosion resistant enclosure. System can be ordered with optional positive air system for enclosure and printhead enabling the system to operate in the most extreme wet or high dust applications found in food and beverage manufacturing as well as industrial applications.

System prints high speed—1, 2, 3, 4 or 5 lines of text, barcodes or graphics. A complete range of dye and soft pigmented inks available in a variety of colors for a wide range of applications. Typical applications mark and code one, two or three shifts per day or 24/7 operations, five to seven days per week, averaging 4,000 – 8,760 hour annual operation. Utilize integrated RS232 and programmable inputs\outputs for remote control and communications.

PRINT CAPABILITIES

LINES OF PRINT

1, 2, 3, 4 or 5 lines of text, graphics and barcodes.

IMAGE HEIGHT

from .06" (1.5 mm) to .75" (19 mm)

NON-CONTACT PRINTING

ink throw distances from .5" (12 mm) up to 2" (50 mm).

PRINT SPEEDS

- up to 1500 feet/ minutes (470 meters/minute) for single line of print

- up to 345 feet/minutes (108 meters/minute) for two lines of print

- up to 173 feet/minutes (54 meters/minute) for three lines of print

- up to 119 feet/minutes (36 meters/minute) for four lines of print

- up to 114 feet/minutes (35 meters/minute) for five lines of print

Systems are simplified to allow anyone to operate, minimizing operator touches, extending time between human interaction.

- CleanStart™—automatically cleans printhead eliminating daily and weekly cleanings.

- 10.4" Color Touch Screen—always on, vivid display with large intuitive buttons and status indicators.

- OneTouch™—single step operator functions reduce operator steps.

- Large Volume Ink Tanks—extend time between fluid additions to weeks or months.

- On-the-Fly External Ink Filling—accomplished in less than a minute with no waste.

- AutoOff™ Go Home Button—automate and eliminate time consuming end of day manual routines.

Designed for the world market the Model 88S Extreme features more than 20 operation and print languages including all Latin based languages, Chinese, Arabic, Cyrillic, Korean, Thai, Vietnamese, Greek, etc. Systems utilize the Unicode character set with capabilities to print over 65,000 different characters and symbols.

BestCode products are backed by CodeProtect™, the industry’s best coding system coverage.

Learn more at www.bestcode.co/model-88s-extreme

About BestCode: BestCode Products are designed and manufactured in the USA, Fort Worth, Texas. For 25 years, the BestCode group continues to produce industry-changing, forward-thinking innovative industrial printing designs. Product designs are focused on ease of use, trouble-free operation, long-term reliability, and affordable cost of ownership with an emphasis on global market requirements.

BestCode products are sold and serviced through a worldwide network of factory-authorized, trained and certified distributor partners. BestCode products are marketed and supported in over 80 world markets. For more information, visit www.bestcode.co (not .com).

For Immediate Release

BestCode Introduces the:

BestCode Next Series 8 Range of Continuous Ink Jet Printing

Systems Small and Large Character Coding and Marking

February 16, 2017

BestCode launches the Next Series 8 Range of Continuous Ink Jet Printing Systems for printing “Small and Large Character” marks and codes. Print real-time “Best By”, “Lot Code”, “Sell By”, “Expiration Codes” and other identifying marks and codes to industrial and consumer goods to ensure product traceability.

The Next Series 8 Range of Continuous Ink Jet Printing Systems bring many new features and capabilities to the coding and marking industry – offering “Extended Operation Times”, “Automated End of Day Routine” eliminating typical manual routines, “New Level of User Simplicity”, abilities to print both “Small and Large Character” information, capability for “True Non-Contact Printing” extending the ink throw distance, and increasing print speeds to “Ultra High Speed” specifications.

Extended Operation Times.

Advanced CleanStart™ extends operation times by automatically cleaning printhead - eliminating daily and weekly cleanings typical in coding machinery. Operate more than 500 operation hours between human interactions.

Automate End of Day Coding and Marking Routine.

BestCode’s AutoOff™ Go Home Button is used at the at the end of the day. Press the AutoOff™ Go Home Button automating and eliminating time consuming end of day manual routines by automatically cleaning the printhead and powering the system off. Press the button and go home – no wait time or manual routines to go through.

New Level of User Simplicity.

Next Series 8 Systems are simplified allowing anyone to operate, minimizing operator touches and extending time between human interaction. A large, 10.4” Color Touch Display is always on, offering a vivid display with large intuitive buttons and status indicators. OneTouch™ single step operator functions are in use throughout the interface to reduce operator steps. A true WYSIWYG environment provides the most realistic view of creating your print message.

Small and Large Character Marking and Coding.

Print marks and codes as small as .025" (.6 mm) – print on the edge of a toothpick or paperclip, and as large as .75" (19 mm) – print on the side of corrugated cases and other large character applications.

True Non-Contact Printing.

Print non-contact, immediate dry, permanent, high speed, reliable marks and codes on a wide range of substrates, including plastic, glass, paper and more. True Non-Contact Printing is ink throw distances at a minimum .5” (12mm) and up to 2” (50mm).

Ultra High Speed Print Capabilities.

Multiple machine types and multiple speed settings enable BestCode systems to achieve the fastest print applications. A single line of text can print at speeds exceeding 2000 feet/minute (600M/minute), two lines over 600 feet/minute (200M/minute), three or four lines of print at 300 feet/minute (100M/minute).

Industrial All Metal, Designed to the Extremes.

The systems are “Built-to-Last” in a compact, all metal, lightweight space saving design. Operate in the most extreme wet and dry applications with an IP55, or IP65 rated enclosure for high dust. Series 8 enclosures are stainless steel 304 as standard and optional models are available using stainless steel 316.

LargeVolume™ ink and solvent tanks.

Extend time between fluid additions to weeks or months even in high volume, demanding print applications. Tanks hold multiple liters of fluids for extended run time. Ink tank volumes can operate multiple months between additions. Makeup tank volumes can operate 1000+ operational hours between additions.

No waste. Bottles drain completely so you can print every drop.